Using a wide array of skills and techniques to accommodate any situation.

Seeing the project through, from start to finish, every step taken, takes us closer to the final result.

With a workshop equipped with machinery ranging from 3D printers (both SLA and FDM), 2 CNC mills and a laser cutter, they give us the ability to quickly and precisely work with most types of material.

Incorporating CAD can sometimes help quickly advance the workflow without actually using any materials until it becomes essential to do so. With rendered or 3D VR imagery, although not quite like the real thing, it can be useful to get better feel for the object before committing to potentially lengthy moulding, 3D printing or CNC milling processes.

Mould making using silicones, alginate and plaster give the ability to replicate with fine detail, many things from buttons and body parts to armour to weapons, allows the replication of the moulded item quickly and cost effectively.

Casting in almost anything is possible, from Fast Cast Polyurethanes and other resins to cold casting bronze or even Pewter if the need arises.

When it’s not possible to take a mould, Photogrammetry allows us to create a digital version of the piece, allowing the process to continue in the digital realm until its realisation in to something tangible.

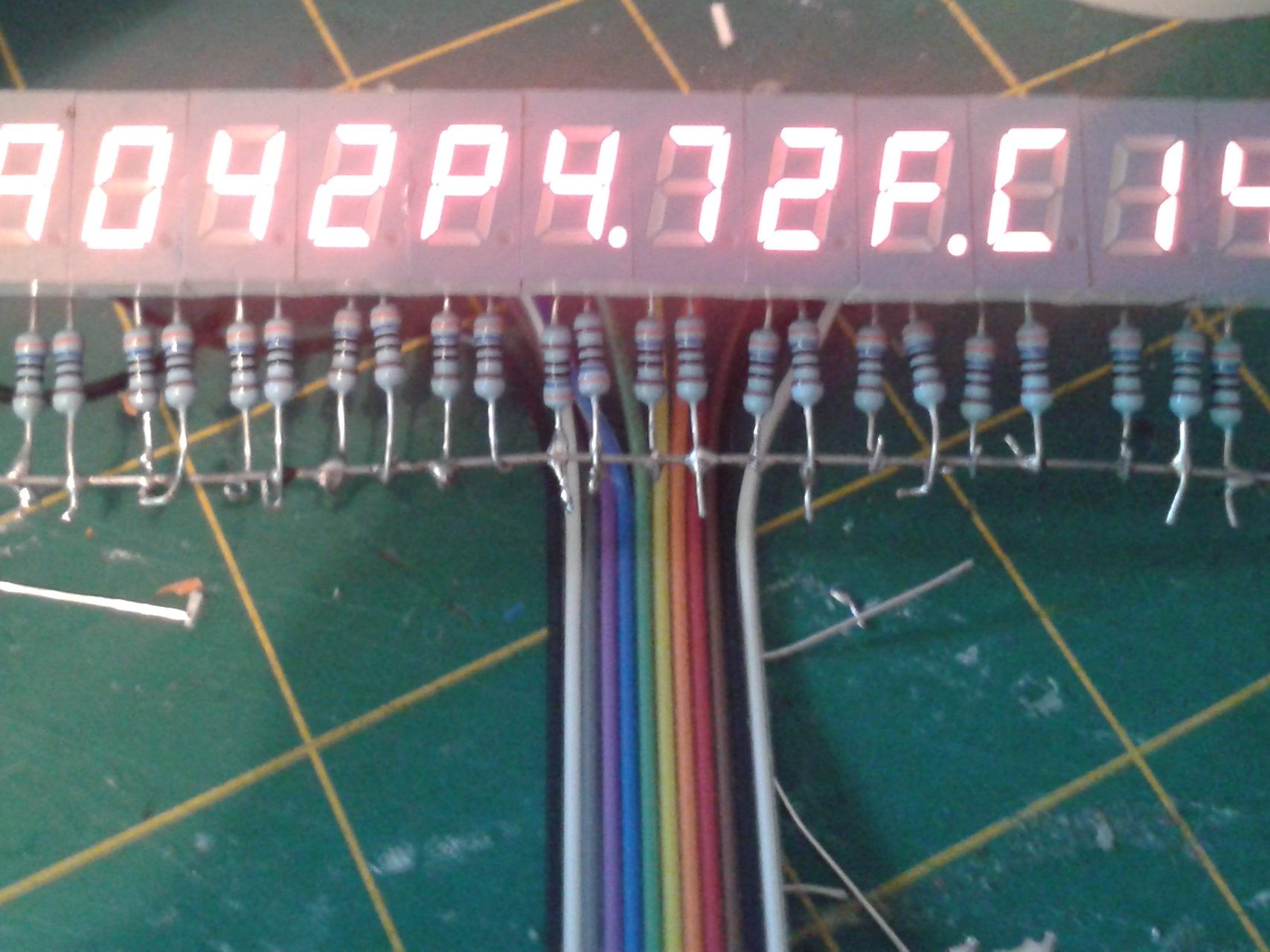

Installation and maintenance of LEDs, EL wire, servos and power packs.

Our services are available form the workshop to on site and on location.